Transporting and using liquid hydrogen requires new equipment (valves, fittings, pumps, etc.).

These components, which come from the aeronautics industry, had been tested at ambient temperature. However, tightness was not guaranteed at the temperature of liquid hydrogen (20K).

Some elements used for liquid nitrogen (77K) are currently used in cryogenics. But do they still work at 20K?

Given the explosive risk of hydrogen, the leak tolerance is stricter than for nitrogen, which is harmless in low doses.

To be sure that these elements are qualified for hydrogen, we have developed a test bench that can measure any leaks for circuit elements at 20K up to 100bar.

The leakage level measured is less than 10-8mbar.L.S-1.

To carry out the test, we used a vacuum chamber 600mm in diameter into which we placed the element to be tested. A 6 mm diameter stainless steel pipe is used to pressurise the device with helium (from 0.2 to 100 bar). Hydrogen could be used if necessary, but helium is easier to use and more effective for leak testing.

Description of the test bench :

The tests were carried out by placing the fittings to be tested in a vacuum chamber as shown below:

|

|

General view of the empty enclosure

|

|

|

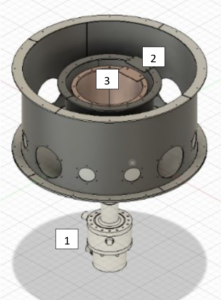

1. Cold head |

Cold head |

|

2. Radiation shield 77K |

Radiation shield 77K |

|

3. Radiation shield 20K |

20K radiative screen |

|

COMPONENTS |

SCHEMA |

|

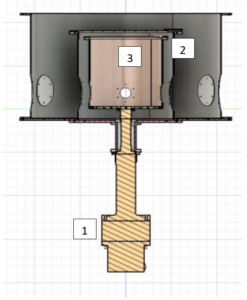

1. Vacuum chamber |

|

|

2. Radiation shield 77K |

|

|

3. Radiation shield 20K |

|

|

4. Elements to be tested |

|

|

5. Helium power supply |

Sectional view of the measuring device with the 3 connection feeds.

Below, view of the measurement zone at 20K with the instrumentation inlets.

|

|

|

1 |

Fittings |

|

2 |

Aluminium temperature sensor support and inserted sensor |

|

3 |

Copper braid/thermal drain |

|

4 |

Electric temperature control resistor |

The fittings are supplied by a 6 mm diameter 316 stainless steel tube. A system of valves enables the 3 fittings tested to be supplied sequentially. The supply also allows the various fittings to be drained of residual helium. Two pressure regulators regulate the pressure. One allows precise adjustment from 0 to 2.5 bar. The other allows adjustment from 0 to 200bar. A precision manometer is used to check the pressure. The supply system can be seen in the photo below :

The photo above (right) shows the PFEIFFER ASM340 leak detector. The minimum detectable level is 1 – 10-13 Pa m3/s. This corresponds to 1.10-12 mbar.L/s. In the foreground you can see the helium supply system and the purge system.

In the centre is the helium distribution system, and on the left is the temperature and vacuum control screen.