For the calibration of our thermal imaging cameras and pyrometers, we use black bodies that we customise to suit our needs. To create a black body, you need a cavity like a ‘dark room’ to trap any incoming rays.

Which blackbody should be used to calibrate a pyrometer or a thermal imaging camera ?

Posté le 19 December 2023 dans News

What geometry for the cavity?

A simple cylindrical hole may suffice, which is what is used on crucibles or high-temperature parts.

Several geometries are possible:

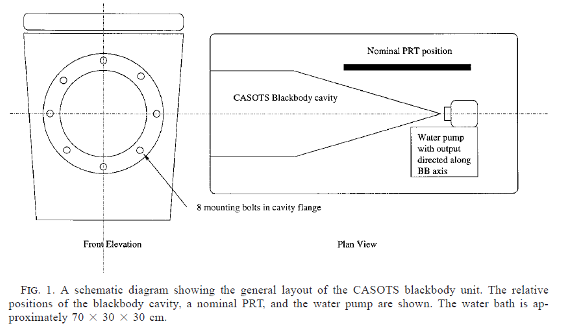

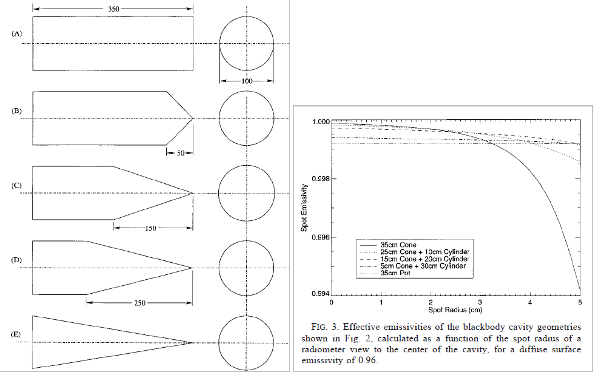

Blackbody drawing from ‘The Calibration and Intercalibration of Sea-Going Infrared Radiometer Systems Using a Low Cost Blackbody Cavity, C. J. DONLON and all, Southampton Oceanography Centre, University of Southampton, Southampton, United Kingdom, 1999 American Meteorological Society’.

Different geometric configurations and the performance of these different geometries.

from ‘The Calibration and Intercalibration of Sea-Going Infrared Radiometer Systems Using a Low Cost Blackbody Cavity, C. J. DONLON and all, Southampton Oceanography Centre, University of Southampton, Southampton, United Kingdom, 1999 American Meteorological Society’.

From the figure above, we can see that the best compromise is a 25cm cone and a 10cm cylindrical part. This obviously depends on whether you want an extended black body with an acceptable emissivity or an emissivity very close to 1 in the centre.

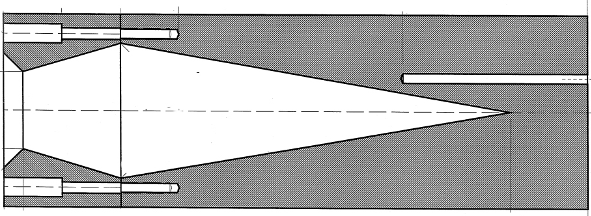

On the model shown in the photo below, we use the inverted cone method to obtain a more compact black body. This model has been mounted on a road temperature measurement device. It can also be used in the laboratory.

Black body before painting

In the laboratory, we use larger black bodies. An example below shows such a device, with a different geometry that allows it to be used at a slightly oblique angle:

The device can be seen painted after the surfaces have been sandblasted to increase the diffusion factor:

What coating should be used on the inside of the blackbody?

You need a sufficiently absorbent coating. Several paints can be used. NEXTEL paint is highly emissive (ε=0.98) and has a constant spectral emissivity between 0.2 and 50µm. The major drawback is its poor temperature resistance.

Another frequently used paint is AREMCO paint, which can withstand temperatures of up to 1300°C, but has a lower emissivity and is more pronounced spectrally.

VANTABLACK is a new paint that can be used and offers very good emissivity. However, its temperature resistance is poor, it is very fragile and therefore unusable for calibration (which varies according to ageing and wear) and its application and use are not without health risks.

For temperatures above 1300°C, few coatings absorb throughout the spectral band. This must be chosen on a case-by-case basis depending on the spectral band of the pyrometer to be calibrated.

Which temperature sensor?

For this purpose, up to 400°C, PT100 DIN B/10 thermocouples can be used, giving a measurement uncertainty of 0.03°C. For higher temperatures, thermocouples adapted to the temperature range are used.

What materials are needed to make a black body?

Aluminium, which is less expensive than copper and can withstand temperatures of up to 600°C, is a good candidate. What’s more, below 600°C the radiative flux is still reasonable and the conductivity of aluminium is sufficient to achieve temperature homogeneity.

For higher temperatures, copper is used, which enables the melting point to be reached (1084°C, but this may depend on the alloy). In addition, its higher thermal conductivity ensures greater temperature uniformity.

For higher temperatures other materials are possible: tungsten (in this case it is necessary to work in a neutral atmosphere such as argon to avoid oxidation), aluminium nitride or boron nitride. The conductivity of the latter materials is fairly high (around 90W/m/K) but particular attention must be paid to the geometry to ensure temperature homogeneity, given the scale of the radiative flux (600kW/m2 at 1500°C) at the outlet of the blackbody.