We have performed the measurement of thermal conductivity of aluminum samples at cryogenic temperatures. The characterizations were carried out on aluminum samples of type 3003 around 77K.

The results show a strong variability of the conductivity at low temperature as a function of the heat treatments undergone by the aluminum.

There is more than 20% difference between the conductivity of the as-rolled aluminum and the aluminum which has undergone an annealing cycle after brazing. Furthermore, it is not possible to predict the thermal behavior at low temperature from a measurement at room temperature.

I. Principle of the measurement

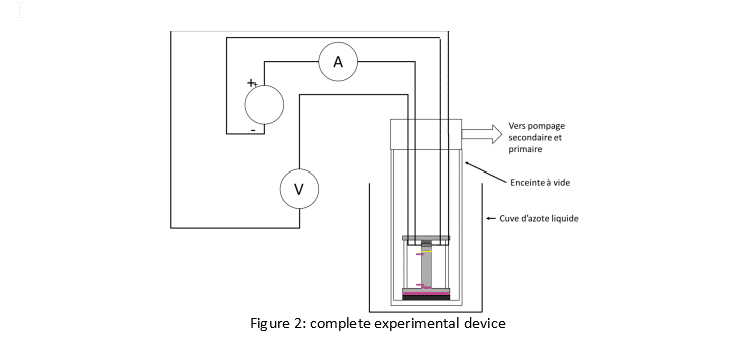

The measurement was made in steady state. Given the temperature, the radiative exchanges are negligible and the work under high vacuum (10-5mBar) made it possible to suppress the exchanges by convection or conduction.

The device supplies a heating resistor with voltage. We carry out the measurements for different powers to obtain several points allowing a linear regression which will lead us to determine the conductivity of the studied bar.

The expression of thermal conductivity λ is as follows:

Where L is the length of the bar, S its surface (section of the bar), P the power read and ΔT the temperature difference at the ends of the bar.

was plotted Δ𝑇 as a function of P to eliminate the calibration deviations of the Pt100 and the residual power provided by the environment at ambient temperature. The conductivity is then written :

Where Slope is the slope of the regression line of the cloud of measurement points 𝑇=𝑓(𝑃).

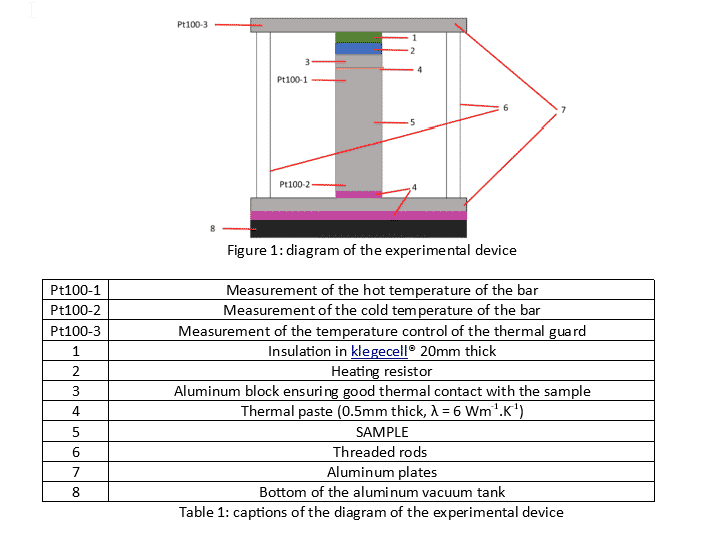

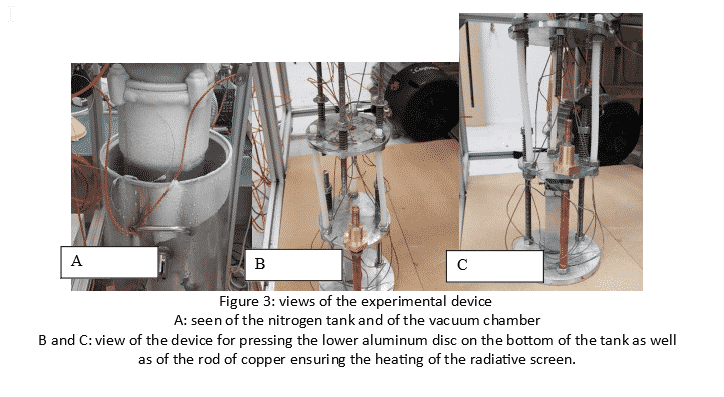

II. Experimental setup

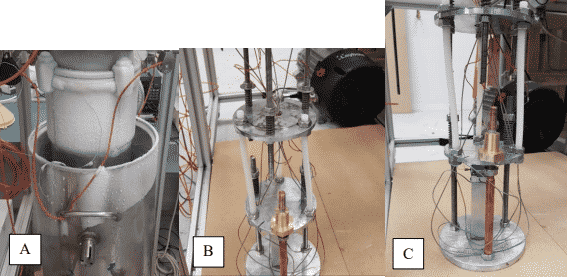

The experimental setup is shown in Figures 1 to 3. Table 1 shows the legends. A 220 Ω heating resistor provides heating with minimum current to reduce lead wires. The power is measured by a 4-wire device. The voltage is measured by a Keithley voltmeter, the current by a FLUKE 179 multimeter. The temperature is acquired by a FLUKE 2638A Hydra series III measuring device. The enclosure is made of aluminum. A flange allows connection to a secondary pumping system consisting of a turbo-molecular pump and a dry vane pump.

The samples are 3003 type aluminum bars of square section 25mm on the side and 100mm long. These bars are drilled with two holes 1.6mm in diameter in order to introduce two Pt100 at 90mm distance.

III. Results and conclusion

The results show a strong variability of the conductivity at low temperature as a function of the heat treatments undergone by the aluminum.

There is more than 10% difference between the conductivity of the raw aluminum rolled and the aluminum which has undergone an annealing cycle after brazing.