Summary:

Our bench for measuring the thermophysical properties of materials can now measure the properties of composites down to temperatures of 10K. epoxy resin is widely used in space applications because of its excellent mechanical and dielectric properties. However, to optimise its use in cryogenic environments, it is crucial to understand its thermal behaviour at low temperatures. This article explores the importance of measuring the thermal conductivity of epoxy in cryogenic conditions and presents typical values at different temperatures.

Introduction:

In the space industry, the materials used are subjected to extreme conditions, particularly cryogenic temperatures. Materials must not only withstand these conditions, but also contribute to the thermal management of equipment. epoxy resin is renowned for its robustness and electrical insulation capabilities, but the thermal management of this resin at very low temperatures requires a detailed understanding of its thermal conductivity.

Importance of Thermal Conductivity in the Cryogenic Environment:

The thermal conductivity of a material defines its ability to transfer heat. In space, where temperatures can drop well below zero, heat management is crucial to the smooth operation of instruments and the safety of missions. Inadequate thermal conductivity can lead to heat build-up or excessive cooling, which can compromise the efficiency of on-board electronic components.

epoxy in Cryogenic Conditions:

epoxy is used in the encapsulation of electrical components and as a structural adhesive material. Its mechanical properties remain stable at low temperatures, making it a preferred choice. However, its thermal properties, particularly its thermal conductivity at low temperatures, are less controversial. At cryogenic temperatures, polymers, including epoxy resins, can exhibit a decrease or increase in thermal conductivity, influenced by factors such as molecular structure and stiffness.

Measuring device:

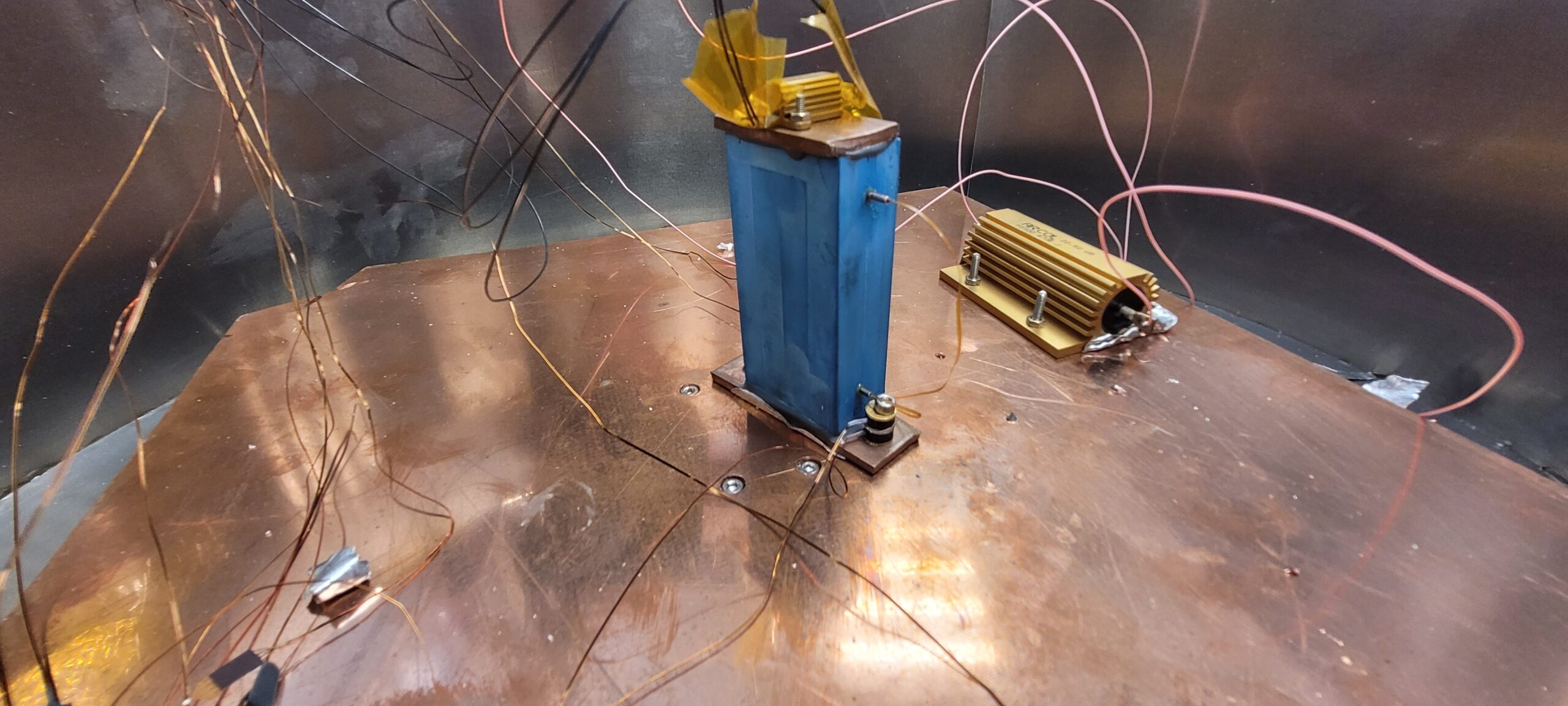

The measuring device is a system that can operate in stationary mode to determine thermal conductivity and in unsteady, sinusoidal or random mode to determine diffusivity, which gives the specific heat of the sample. This device can be seen in the photo below.

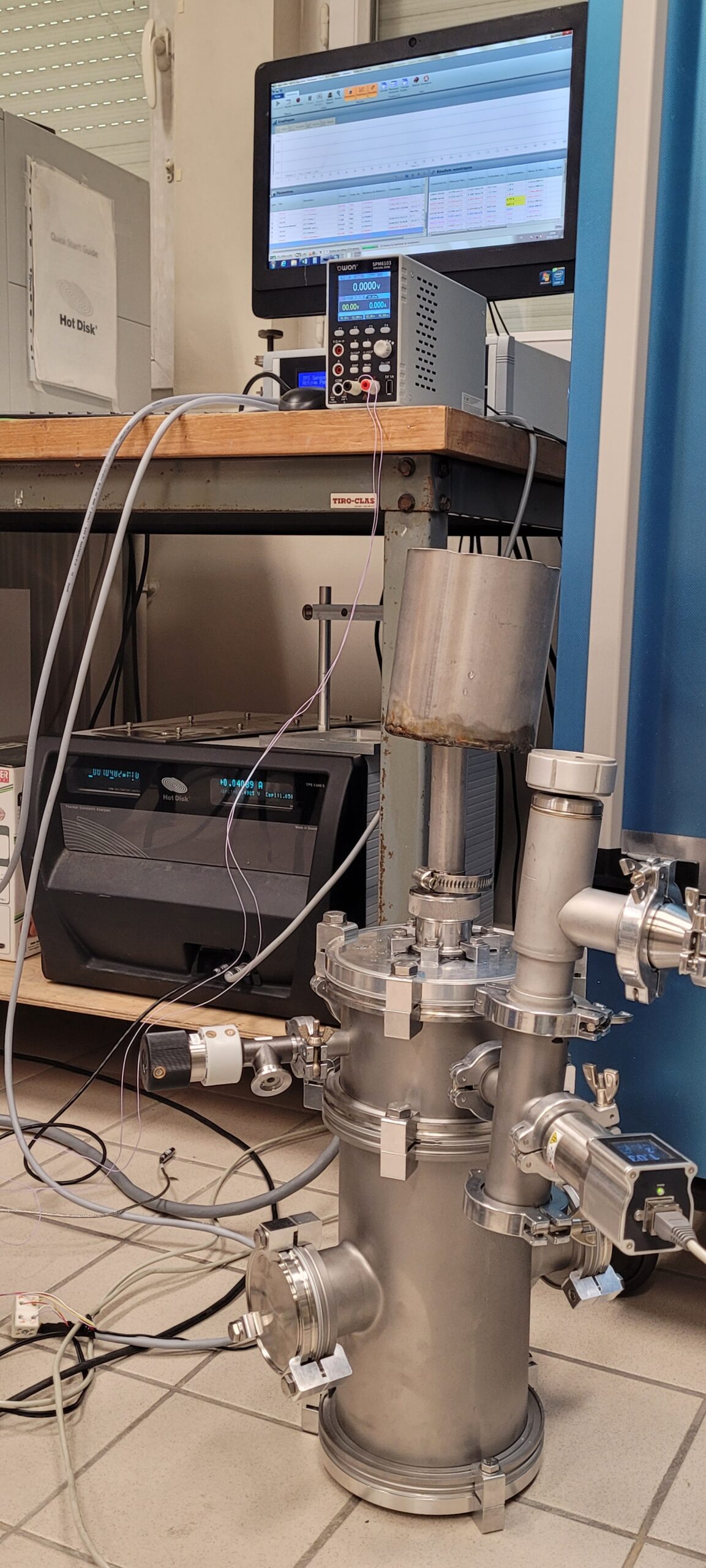

To complete measurements at temperatures close to room temperature and up to 77K, we use the HotDisk. We have developed a vacuum chamber fitted with a cryostat that can reach 77K. The cryostat can be seen in the photo below:

Thermal conductivity values for epoxy :

Although the thermal conductivity of polymers is generally low compared with metals, it varies with temperature. For epoxy , typically at room temperature (around 300 K). At even lower temperatures, close to 4 K (used in advanced cryogenic applications), it could decrease further, underlining the importance of a specific analysis at the application temperature.

Conclusion:

Thermophysical characterisation of epoxy under cryogenic conditions is essential for space applications. Understanding how its thermal conductivity varies with temperature enables us to better design thermal systems for satellites and other space devices. Efficient thermal management ensures not only optimal equipment performance but also the success of space missions. Further experimental studies are recommended to further explore the thermal behaviour of epoxy at various cryogenic temperatures in order to refine existing models and develop advanced materials adapted to the rigours of space.

Other articles about conductivity:

Measurement of the thermal conductivity of aluminum samples at low temperature

Measurement of the thermal resistance of super-insulators for storing liquid hydrogen in cryogenic conditions

THEMACS at the Service of ESA for Cryogenic Devices