Thermal modeling of a track de-icing system

Posté le 11 May 2020 dans News

Thermal modeling of a track de-icing system for tire trams

The winter risk for roads and treads for tire trams can be combated either with fluxing agents (salt, brine, organic fluxing agent, etc.) or by heating in undercoat. The first solution has many drawbacks. Salt corrodes the braking systems of trams and organic fluxes disrupt the return to earth of the power supply via the central roller. To this is added the environmental question.

The solution of heating by heating cables implanted in the tread is the most practical method to implement. However the dimensioning requires a modeling in finite elements.

THEMACS Engineering has developed for FLEXELEC Groupe Omerin, manufacturer of heating cables, a tool for modeling the thermal behavior of a pavement.

FLEXELEC Groupe Omerin supplier of frost protection systems is now able to provide an optimized solution from an energy point of view.

The problem to be solved:

The treads consist of a reinforced concrete sole in which heating cables of a certain linear power have been immersed. For maintenance reasons, it is possible to immerse metal tubes into which the heating cable is introduced. This facilitates maintenance. Figure 1 shows an example of a tread placed on an embankment.

The solution proposed by THEMACS engineering:

To simplify the model, we have not dealt with edge effects. We considered the roadway as an infinite series of heating cables aligned in the concrete.

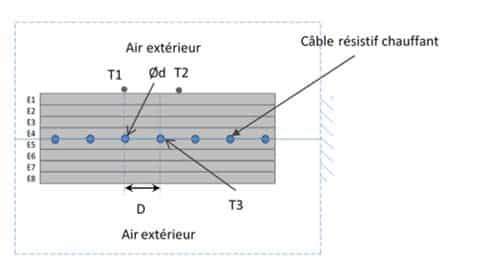

A schematic section of the road is presented in figure 1. There is air under the tread and this is not an error! Indeed in the case of viaduct the tread is suspended. The layers E1 to E8 represent the possible differences in the thermal behavior of the concrete. The E8 layer can be increased (1m or more) to represent the semi-infinite embankment (similar to Figure 1).

The parameters of the simulation are the thermal properties (thermal conductivity, thermal capacity, density) of the different mineral layers (from 2 to 8 layers), the linear heating power (supplied directly or calculated from the linear resistance in Ω / m, length and supply voltage), and the geometric dimensions of the problem:

- the diameter of the heating cables

- the distance between the heating wires

- The thicknesses of the different layers E1 to E8

The output parameters are:

- Temperature profile at the vertical of a heating wire

- Temperature profile between two heating wires

- Temperature profile on the surface of a heating wire

- Evolution of the temperature over time at different points on the road.

The exchanges on the lower and upper surfaces of the concrete tread are carried out with air. The convective exchange coefficients are to be configured as a function of the assumed wind speed. Radiative exchanges are also taken into account.

An exchange coefficient by convection is chosen on the upper and lower face.

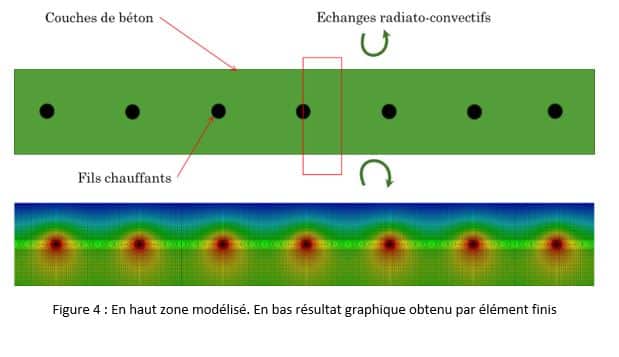

The modeling tool used is CASTEM developed by the CEA. This tool makes it possible to model by finite elements the thermal behavior of the studied geometry.

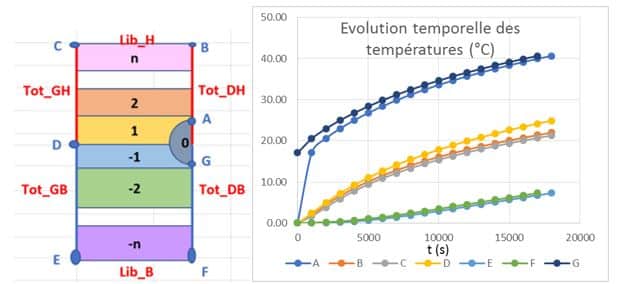

The user interface is provided by an Excell sheet which allows to size all the system. The parameters are exchanged with CASTEM using CSV files. These are read and processed by the CASTEM program. Figure 3 shows the modeled area (area framed in red) This can be reproduced by symmetry to model the entire roadway.

Example of modeling results:

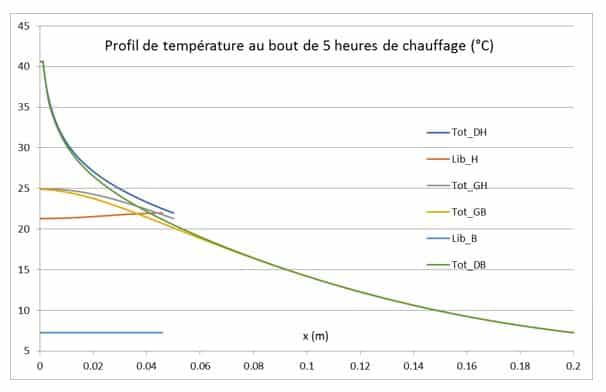

Using our tool, we have modeled a concrete pavement with 50mm of concrete above the heating cables and 200mm of concrete below. The temporal result is visible in Figure 4 and the temperature profiles after 5 hours are visible in Figure 5.

This modeling makes it possible to better size the power to be injected into the concrete, find the right compromise to have a uniform rise in temperature on the surface and improve the geometry of the heating system.

Figure 5 : example of temperature profile within the concrete pavement after 5 hours (the labels correspond to those in Figure 4.

Conclusion :

This tool makes it possible to size the heating systems to best ensure the de-icing of the roadways. This could also apply to roads, airport runways and sports grounds in order to optimize the heating systems.

The modeling must be accompanied by a system for measuring the thermal properties of the substrate (thermal conductivity heat capacity, etc.) in order to best supply the model. In fact, depending on the quantity of reinforcement included in the pavement, the effective thermal properties change significantly.